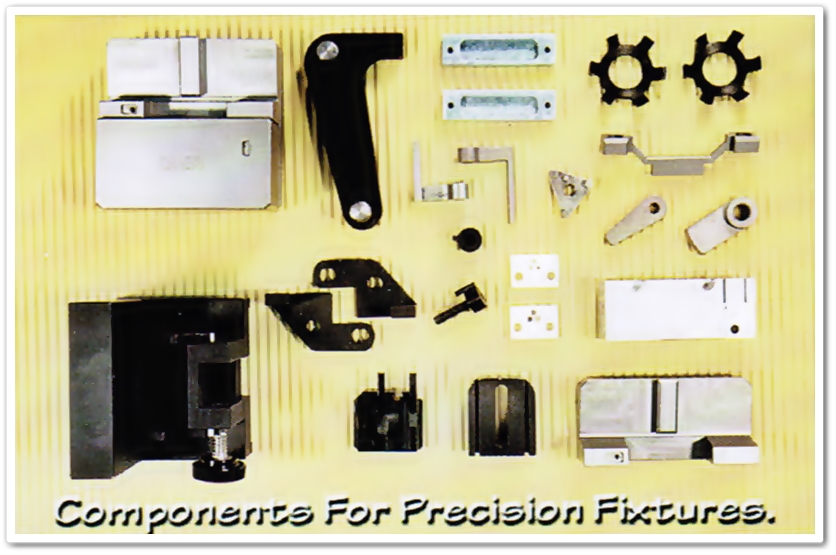

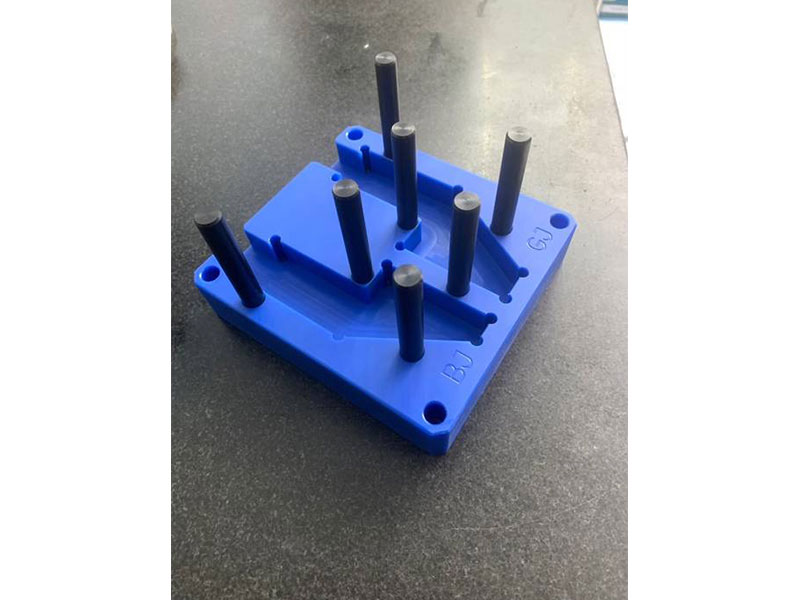

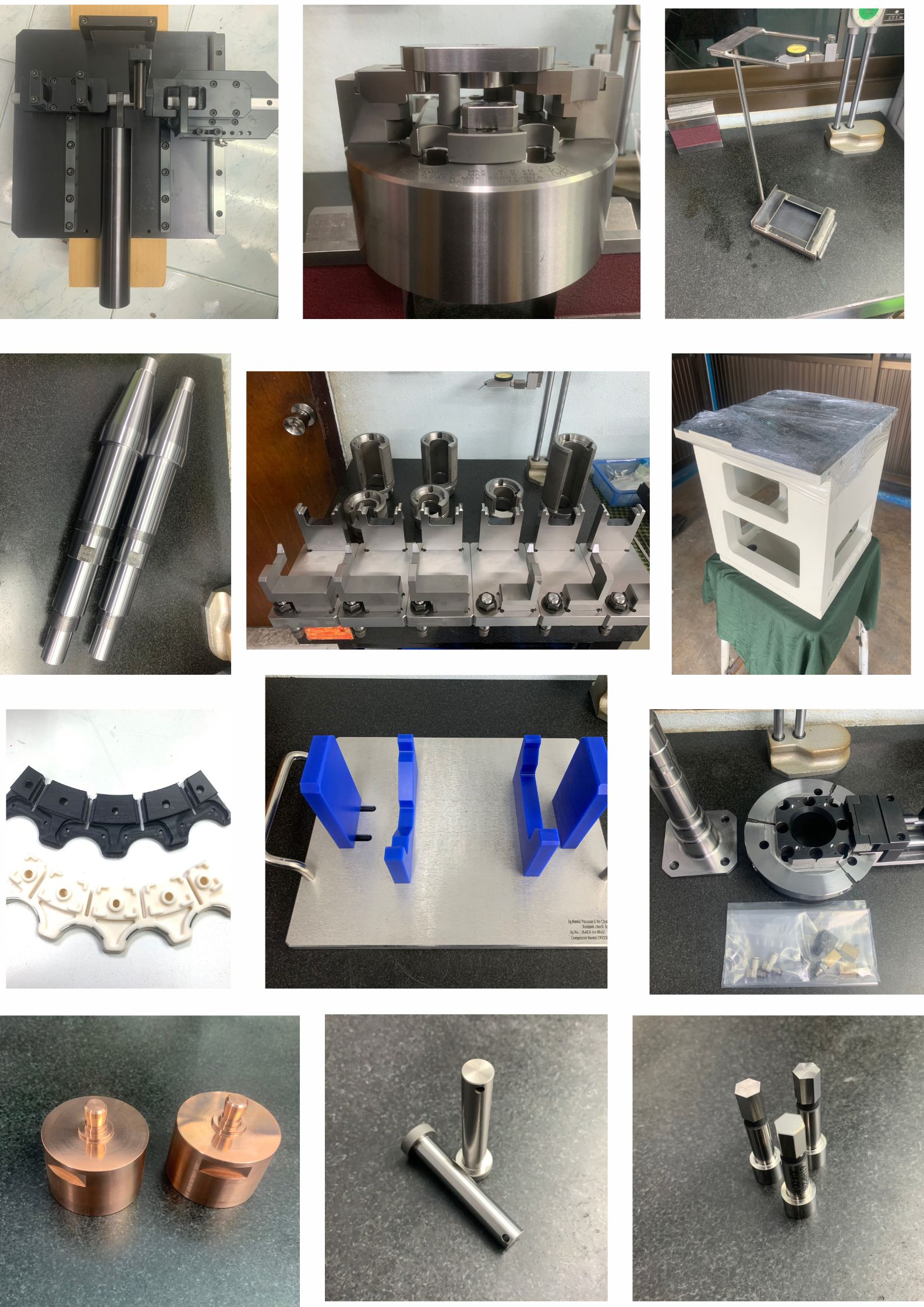

We Have more machines, more facilities equipments and more tool makers.

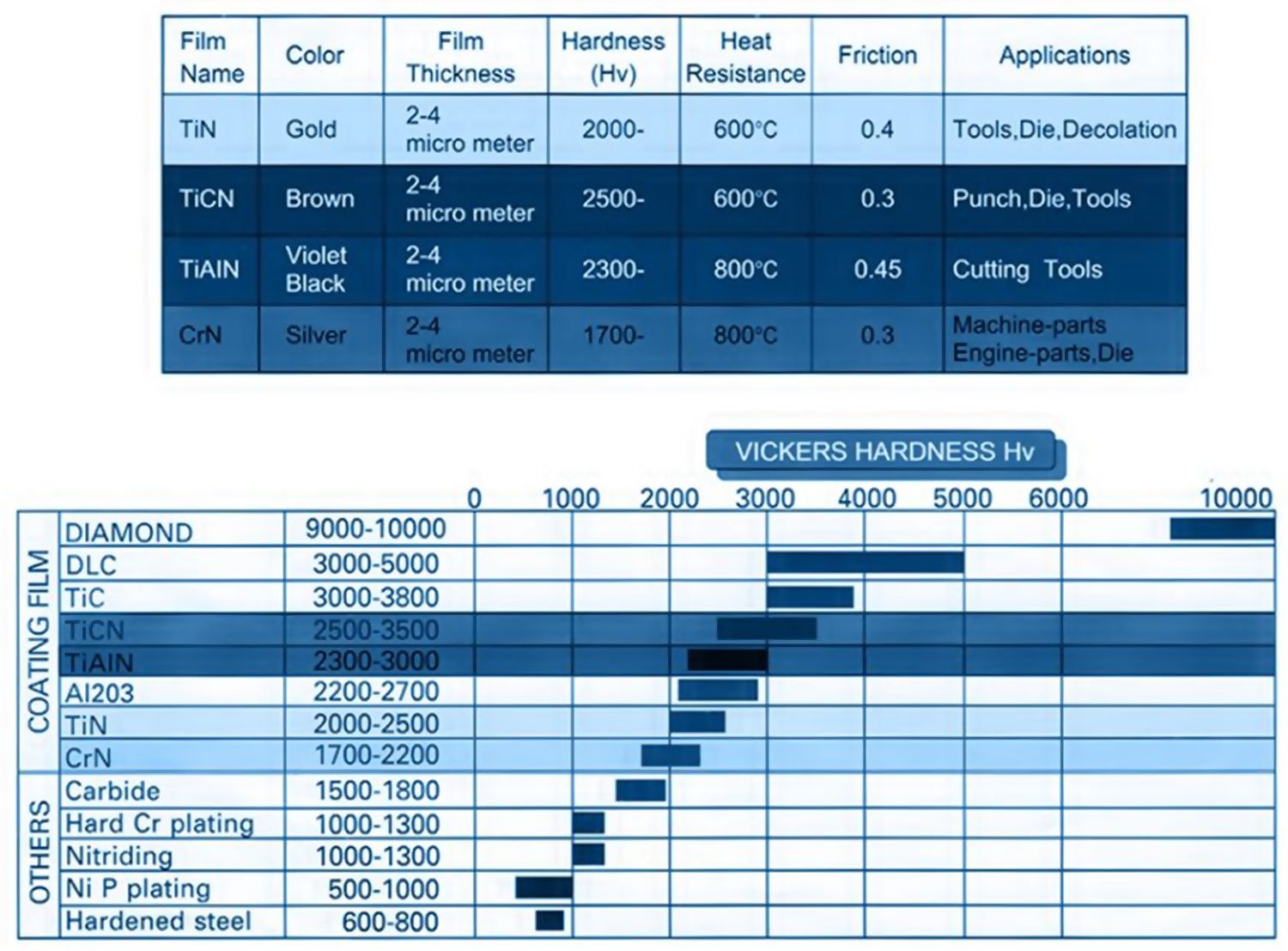

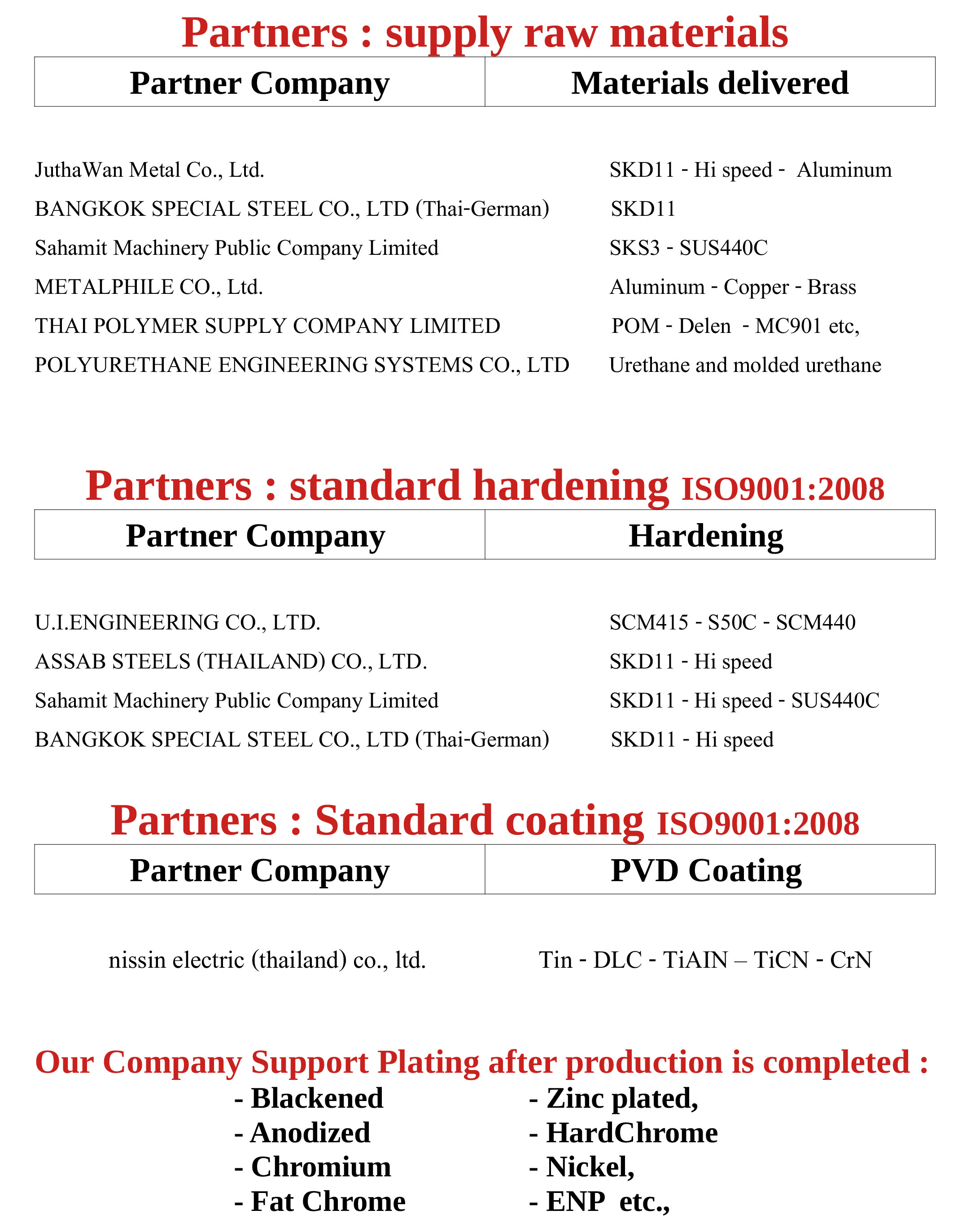

"Physical Vapor Deposition", also known as PVD, is the process of creating thin films for various purposes, such as hard coatings for wear protection or films with specific electrical properties. A wide range of coating materials can be selected, from metals, alloys, and certain compounds, and the intended use determines the material to be used to produce the thin films.

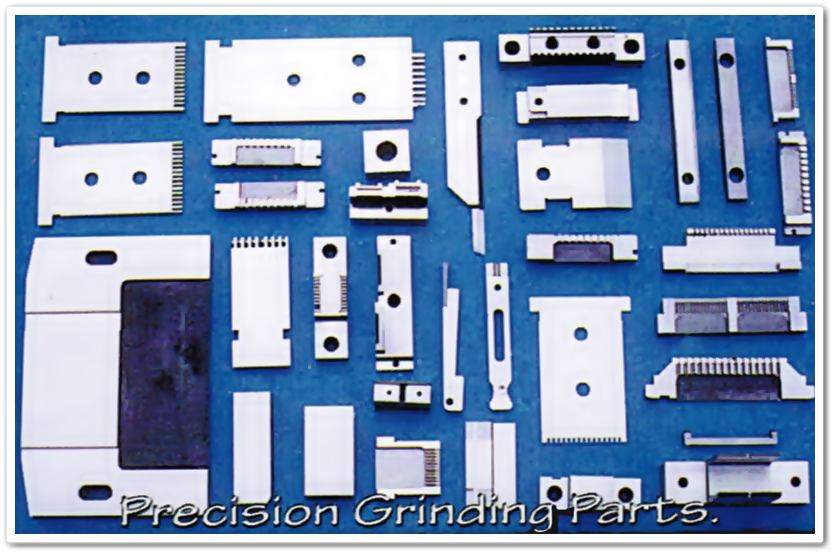

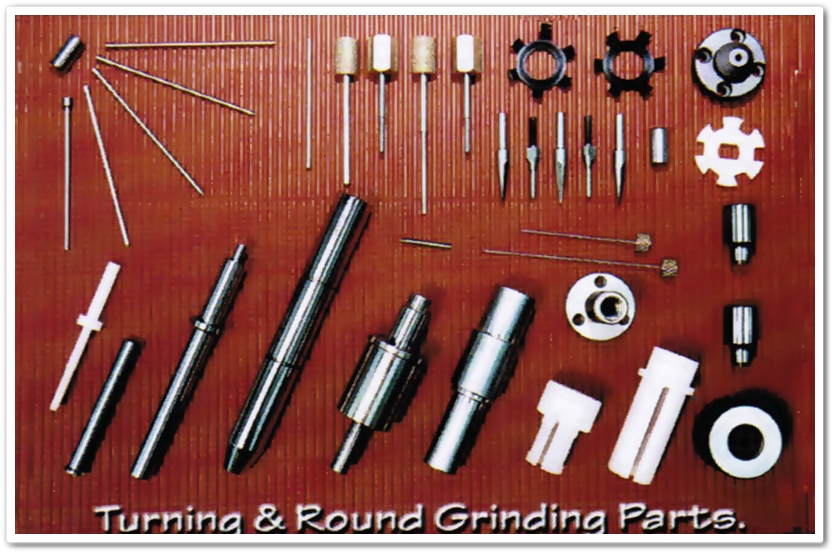

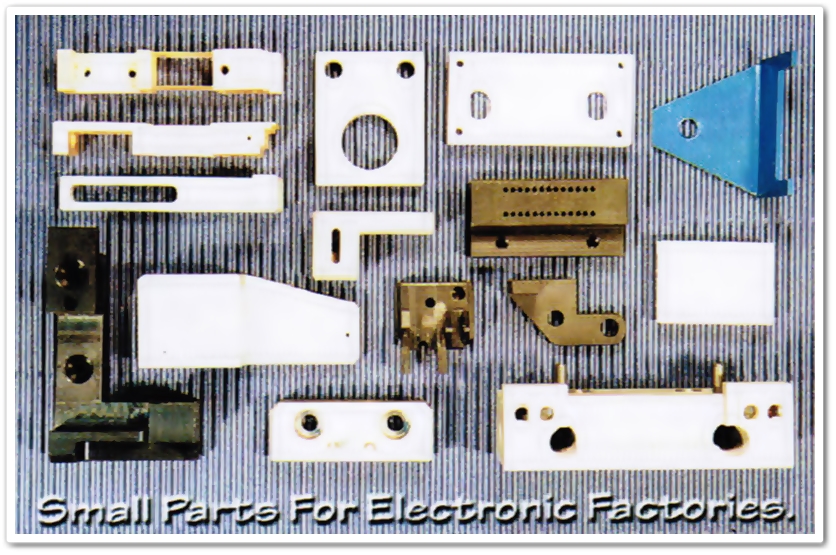

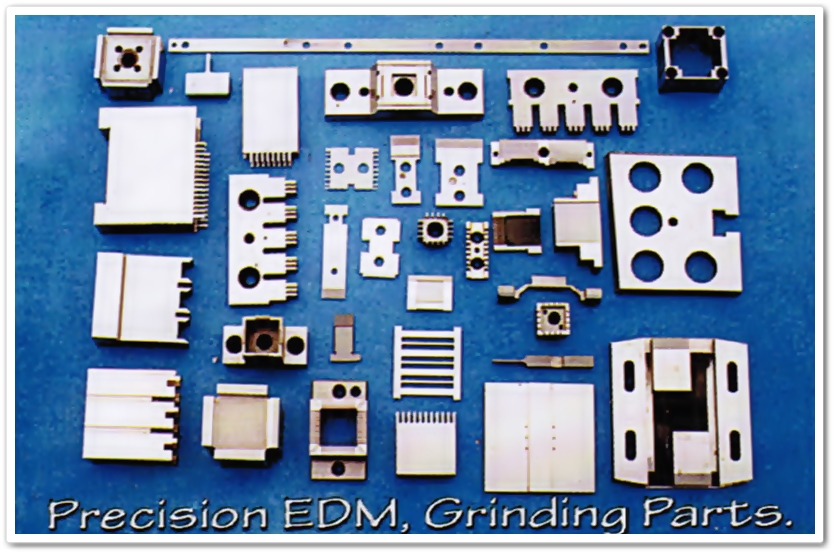

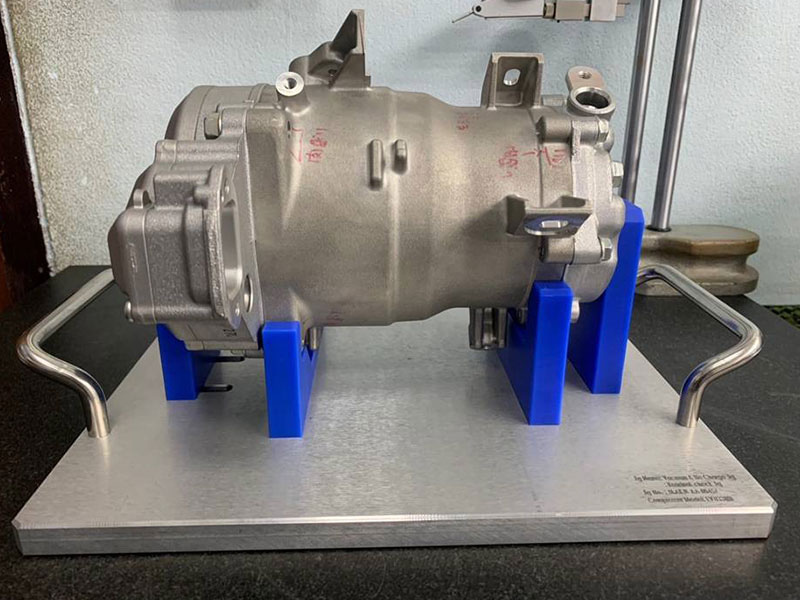

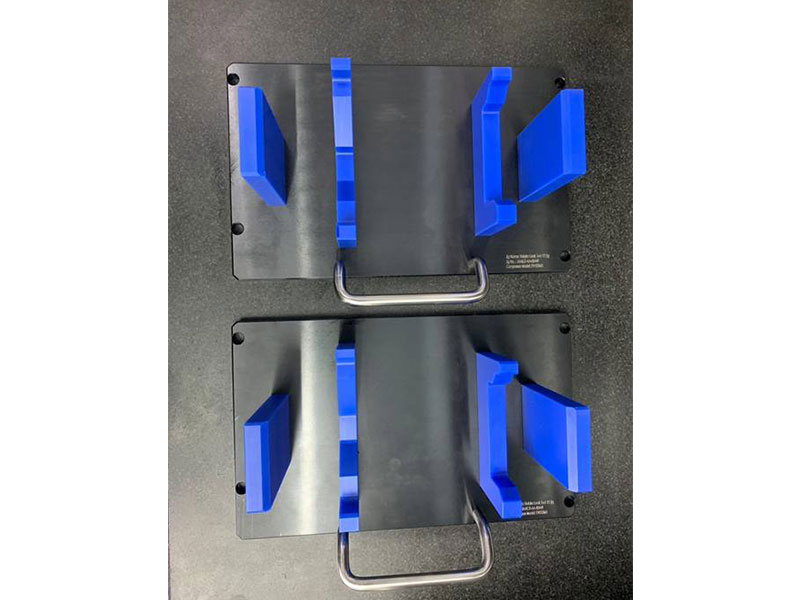

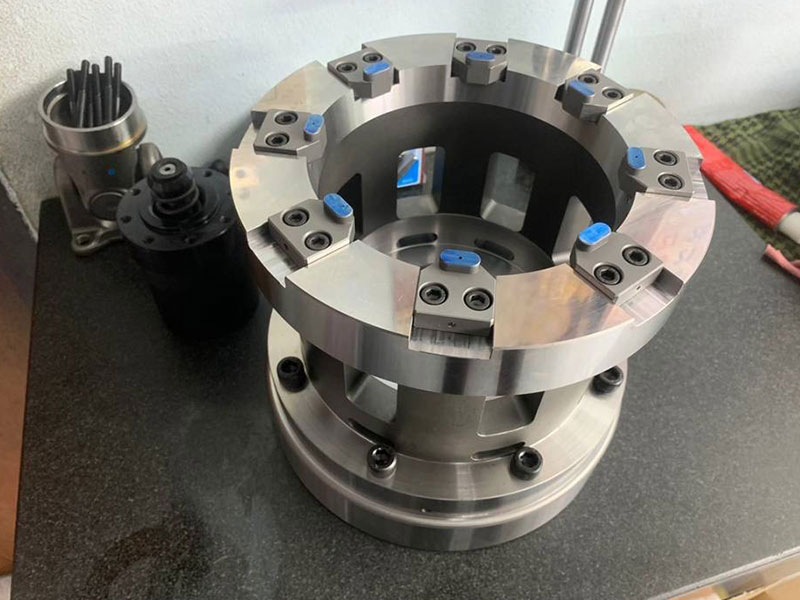

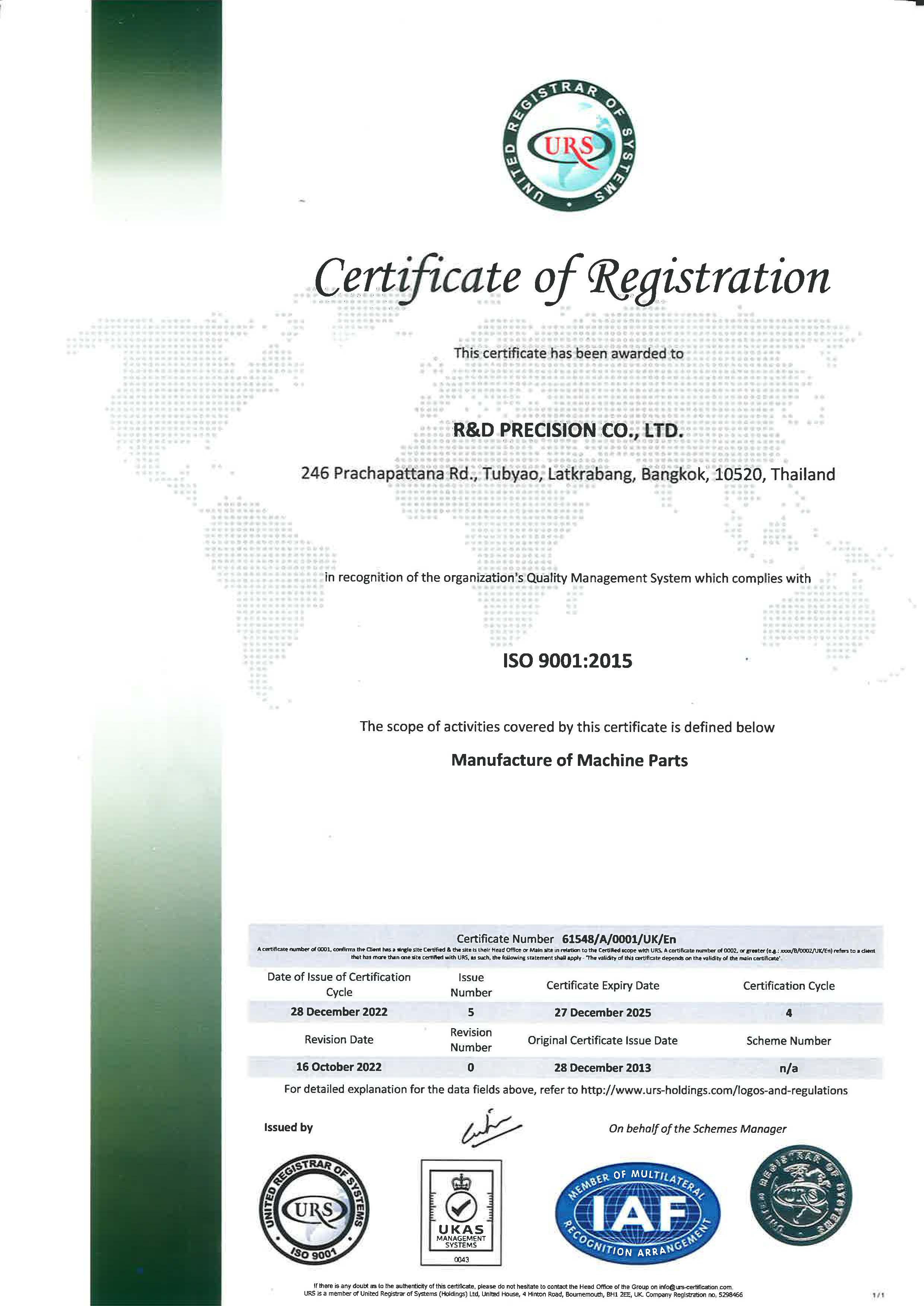

Was established on August 8, 2008 and received ISO9001:2008 on December 28, 2013. Certificate No.61548/A/0001/UK/En is a company that manufactures and designs industrial machinery parts such as PUNCH, DIE, JIG FIXGER, SPARE PART, PLUG GAUGE, PITCH GAUGE, SNAP GAUGE, PROFILE GAUGE and other works according to the model or sample.

Vision : Quality products, systematic management, on-time delivery, continuous development, 30 employees, managed by Mr. Bandit Liamsawan, who has more than 20 years of experience. He has worked with and worked with engineers in the production line of industrial parts with many leading companies such as Seagate, Western Digital, Nidec, Fujisu Denso, Hino, Image Precision, KYB, Asahi, Crown, Toyota, Honda, Haadthip, Ingon, etc.

CROWN Bevcan and Closures (Thailand) Co., Ltd.

Sunstar Engineering (Thailand) Co., Ltd.

Sangprateep Auto Seat Co., Ltd.

IDAKA (Thailand) Co., Ltd.

Asia Maintenance Co., Ltd.

Asahi Intecc (Thailand) Co., Ltd.

JUTAWAT Management Co., Ltd.

JUTAWAT Solution Co., Ltd.

R&D Muti Assembly Co., Ltd.

ETO ENGINEER (THAILAND) CO.,LTD.

JOZU Auto Part Co., Ltd.

Watanabe M&E (Thailand) Co., Ltd.

Blowpack Co., Ltd.

BERNINA Thailand Co., Ltd.

Bangkok Eagle Wings Co., Ltd.

R.J. London Chemicals Industries Co., Ltd.

DFT (THAILAND) Co., Ltd.

FCC (Thailand) Co., Ltd.

GPV Asia (Thailand) Co., Ltd.

NT SEIKI Co., Ltd.

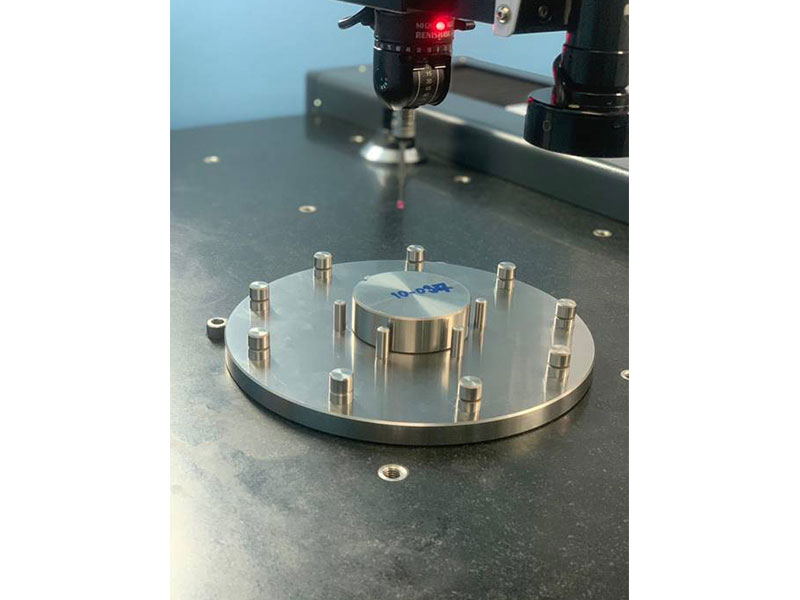

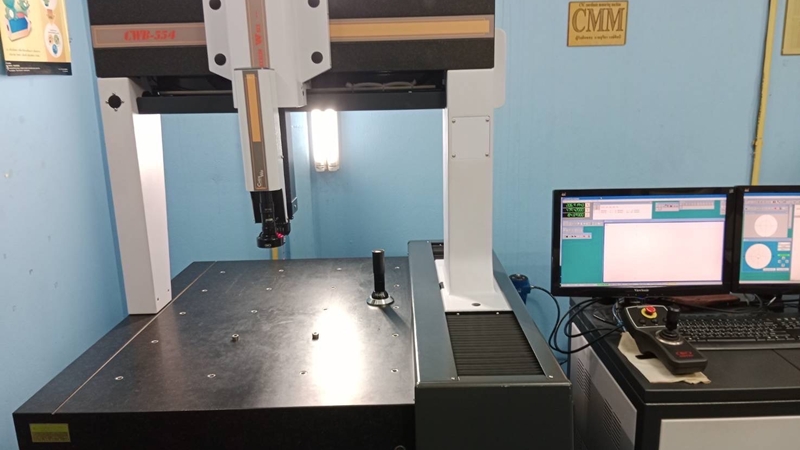

NEW CMM

NEW MICRO SCOPE

NEW LASER MARK

Measuring Tools

Machinery used by

R&D Precision

Materials that can be machined include Aluminum, Steel, Stainless steel, Copper, Sheet metal, Brass, Bronze, Wood, Nylon, Polycarbonate, Polystyrene, Acrylic, Plastic and many more.

Selecting the best material for your workpiece is a challenging task. Generally, the decision to select a material is based on main factors. For example, if price and hardness are the main factors, the material selection must include these two factors. Click on the material menu on this web page, which will have material specs, properties, etc. to use as reference information for you.

Can work for you in the following ways: Drilling, Cutting, Machining, Stamping, Tapping, Milling, Turning, Pressure Die Casting, Counter boring, Counter sinking, Edge cutting.